ShivamPandey

Members-

Posts

24 -

Joined

-

Last visited

Recent Profile Visitors

100876 profile views

-

If we need to connect 6 strings of 15 modules to three MPPT inverters, which option should we use between Power sharing between MPPTs and within the inverter Should we choose independent MPPTs and or a single inverter with power sharing within the inverter? Technically, no power sharing will be done as all MPPTs havethe same amount of power, but does choosing between these make or create any difference in simulations or productions?

-

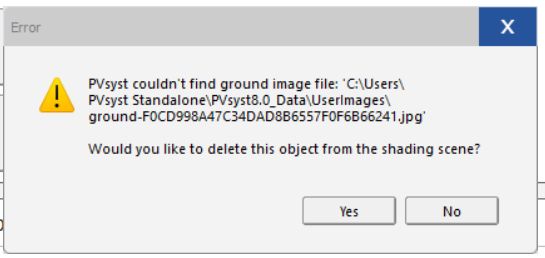

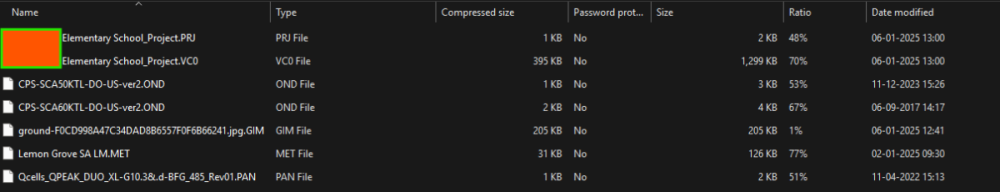

Hi I have an older Pvsyst project export zip file, but when importing it into PVsyst, it is showing the following errors. Older project is created witjh PVsyst 8.0.5 Zip Folder contains all the files exported. Same is the issues with the background image imported from map service within the near shading. Map is not showing up when imported into a different machine or PVsyst

-

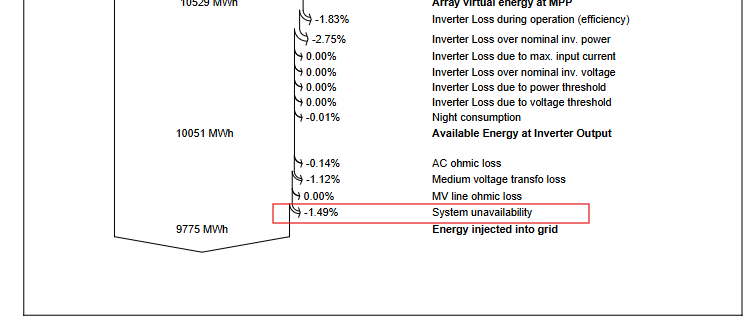

We need to maintain the plant unavailability in the PVsyst loss diagram between 1.45% and 1.50%, with no flexibility on this requirement. Currently, we are adjusting the date and time to achieve the correct values. Do you have any alternative methods to reach these numbers? The unavailability time fraction and periods are fixed at 1.5% and 1, respectively.

-

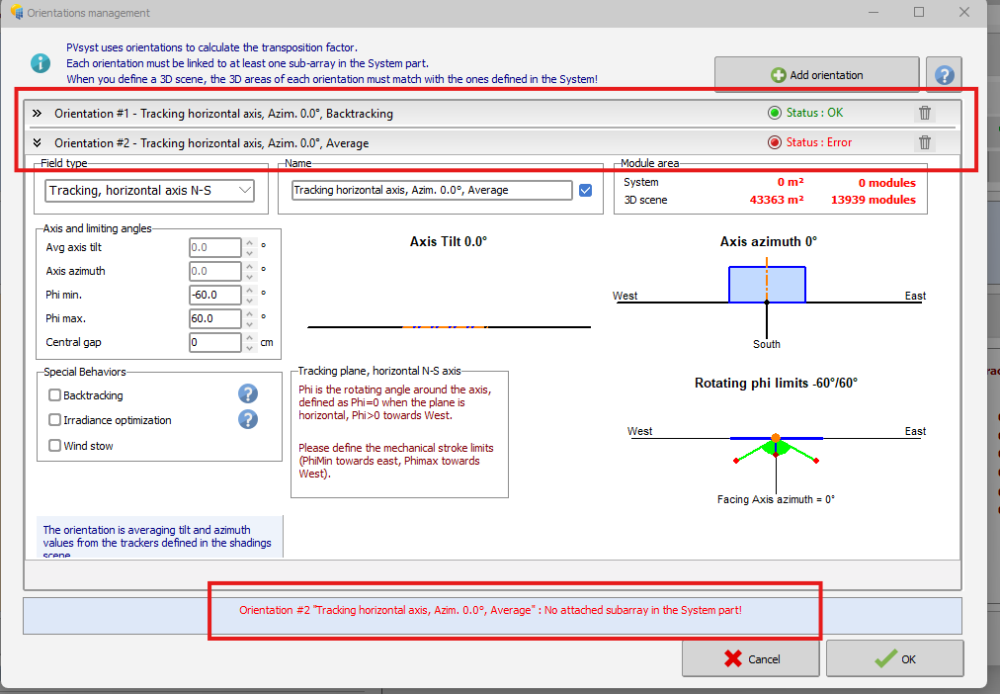

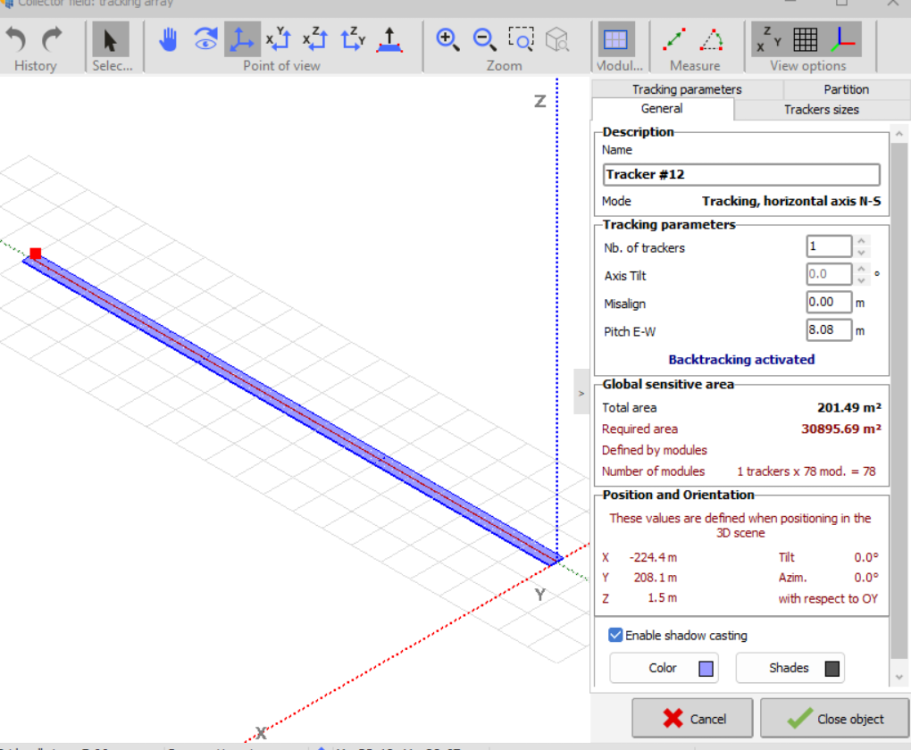

After importing PVC file, getting this error, "Orientation #2 "Tracking horizontal axis, Azim. 0.0°, Average": No attached subarray in the System part!". But in the orientation tab, every parameter is the same. See below snip. There are two orientations one has backtracking and another with average. I deleted orientation 1 from the 3D scene and all trackers from orientation 1 to orientation 2 with average and selected average from the pop-up received. What is the reason behind it even when all parameters are the same?

-

What should be the correct approach for the partition of half-cut cell modules in fixed-tilt tables. For 2P*13 table size, strung in U 4*number of modules per string i.e. 4 in the Y axis and 13 in X axis For 2P*26 table size, strung in U 4*1 i.e. 4 in the Y axis and 1 in X axis

-

Just for reference, once opacity is set to zero again in the near shading, we need to simulate the project again (This might cost hours with larger size or module layout just to remove the background from the report). Please fix this also if possible.

- 2 replies

-

- near shading

- near shading 3d scene

-

(and 2 more)

Tagged with:

-

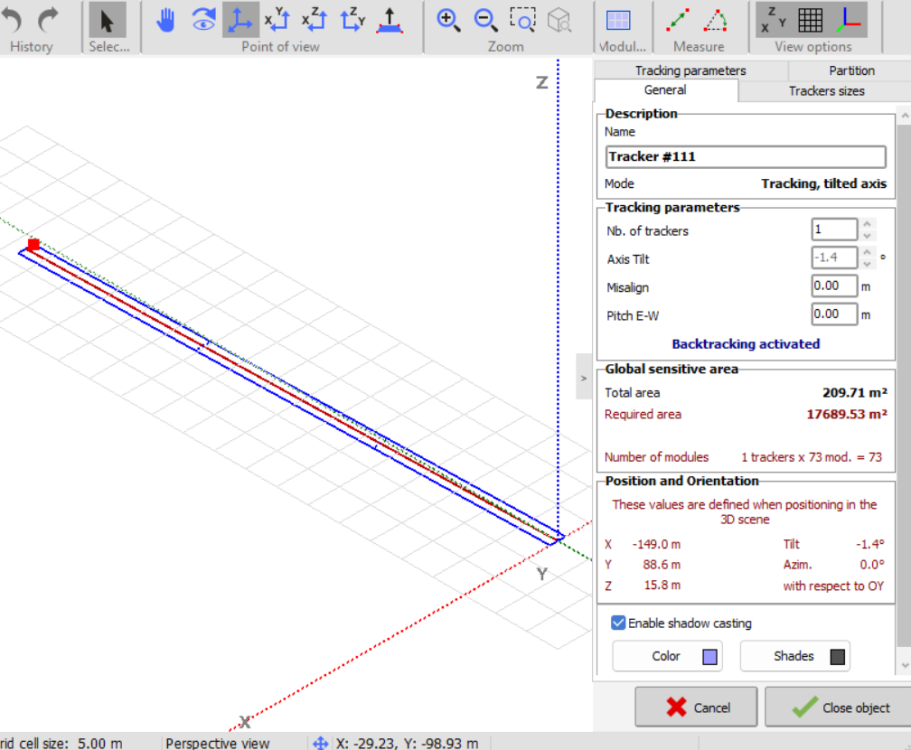

PVcase imported trackers do not have pitch defined when going in the modify object. Does it impact backtracking? I have heard from a few industry people that it does not do the backtracking as it does not have the pitch defined (or not an array of the trackers) and all the trackers are ungrouped and are not an array of trackers Also if I ungroup an array of trackers which was created in PVsyst near shading, does this affect the backtracking? See the below snip for reference Pvcase export An array of trackers was created in Pvsyst and then ungrouped

- 1 reply

-

- backtraking

- backtracking

-

(and 3 more)

Tagged with:

-

Albedo from project setting to varient bifacial model

ShivamPandey replied to ShivamPandey's topic in Suggestions

Just for my understanding, is it possible to have different albedo for the far and bifacial model or it should be the same if we have albedo values available? Project setting albedo is used for simulation even if modules are mono-facial. -

Why Albedo from the project setting is not copied to the variant bifacial model, we always have to enter values two times. If we need to edit a variant albedo, we can do it manually later during variant design. What is the use of project setting albedo?

-

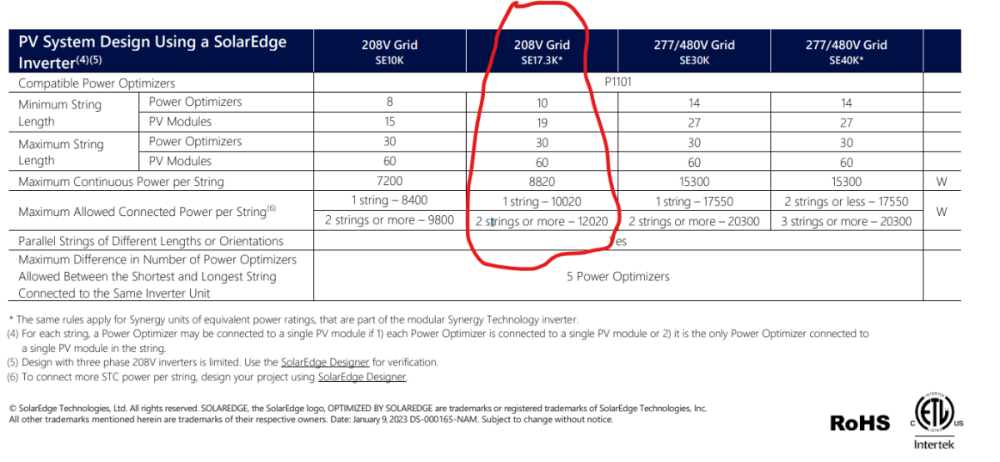

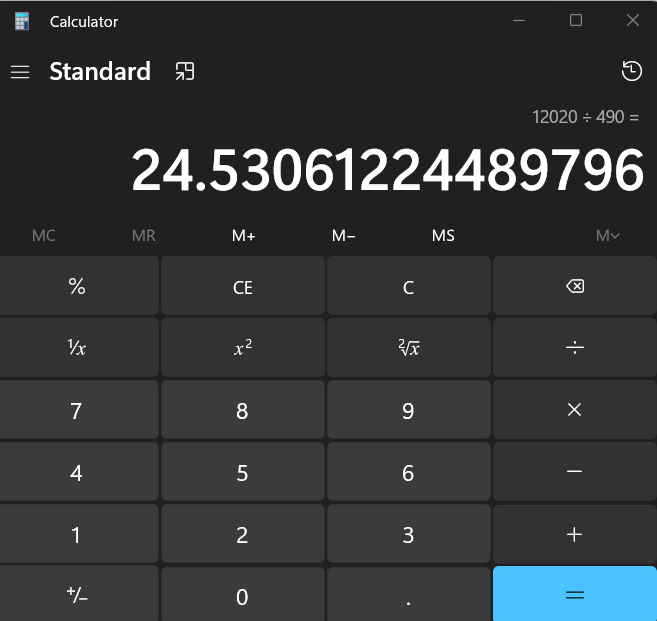

I ran into the same problem. Solaredge tool itself allows for more than 11 optimizers per string. You can confirm with the optimizer datasheet. For 490W modules, we can connect up to 12020W per string if each unit has at least two strings. Also, PVsyst does not allow connecting an odd number of modules per string. (EX- 19 modules per string, last module with single module per optimizer) Please suggest

- 3 replies

-

- solaredge

- oversizing

-

(and 1 more)

Tagged with: