-

Posts

2075 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

First of all, the definition of the "Solar Fraction" SF = EUser / ELoad is valid for Grid-connected systems. In Stand alone systems this is more complex: it is the Output of the PV system (EOut converter), minus the battery energy balance: SF = ( EOutConverter - EBattCharge + EBattDischarge ) / ELoad. The battery balance (EBattCharge - EBattDisch) includes the difference in SOC between the beginning and the end of the interval, and the battery losses. Therefore: - Over la short period, the Solar fraction is not relevant because of the battery SOC difference, - Over a long period, the SOC difference contribution becomes lower, but may still alterate the real value of the Solar Fraction. Now the battery losses are extremely difficult to evaluate, especially due to the variability of the effective capacity of the battery according to the Charge/Discharge rate: in PVsyst this is an approximation, which may sometimes lead to "positive" battery losses in some cases (depending on your load profile definition). This seems to be the case in your project, where the differences are very low (some few permille). See the Help https://www.pvsyst.com/help/physical-models-used/batteries/battery-model/battery-efficiency.html?h=battery

-

Temperatures when simulating DC cable losses

André Mermoud replied to AhmadMick's topic in Simulations

In PVsyst, the cables temperature is fixed to 50°C at any time, supposed to be an "average" during all conditions of the simulation In the reality, the wire temperature is obviously not well defined: it depends on the wire mounting mode, the possible exposition to the sun, the current, etc... The sensitivity of the resistivity to the temperature is 0.39%/°C, for the copper as well as for the aluminium. See the help https://www.pvsyst.com/help/project-design/array-and-system-losses/ohmic-losses/metal-resistivity.html?h=resistivity NB1: in a next version, it will be possible to choose the temperature for any part of the wiring. In the present time, you can modify it in the advanced parameters. NB2: the wires temperature has nothing to do with the cell's temperature in the module. -

This parameter "Maximum current per MPPT" is indeed quite correlated to the "Minimum voltage for attaining PNom". See the help https://www.pvsyst.com/help/component-database/grid-inverters/grid-inverters-main-interface/grid-inverters-main-parameters/index.html#input-side-dc-pv-array Now if this is specified, PVsyst will apply this cutrremt limit during the simulation. But this rarely produces "Inverter losses due to current overload", as this limit is most of the time preceded (masked) by the Power overload limit. See the Help https://www.pvsyst.com/help/physical-models-used/grid-inverter/inverter-operating-limits.html If the limit is not specified, it is obviously not applied. Now this limit is not always well "understood" by the manufacturers who submit their data, nor well defined in the datasheets. Sometimes we have to add this information afterwards in the database.

-

PVsyst is a software for the study of PV systems. It is meant for the storage of PV energy, not the grid energy. It is not a suited for the simulation of any BESS systems on the grid.

-

What dou you mean by "Types of cables" ? The different types of cable (of a same metal) have in principle the same resistivity, and this is the parameter which determines the power loss. If you are talking about the installation mode: - The resistivity may indeed depend on the cable temperature, and therefore on the installation mode. - The main thing to be considered will be the current limit for a given cross section, which is specified in norms.

-

In the DC circuit (array of strings), the total wire length is indeed the lenght of the whole loop (this si mentioned just below "Please specify the total wire length for each circuit. " For the AC circuit, this is the line length (distance between devices).

-

mismatching night consumption at same AC capacity

André Mermoud replied to mohaned's topic in Simulations

Probably you have defined your transformer by a generic relative loss, i.e. proportional to the transformer nominal power. And this nominal power - evaluated by PVsyst on the basis of the PNomPV at STC, or the PNomac (this is your choice in the Project's settings) - has been changed in your different runs. This should not arise if you define an explicit transformer from the datasheets, the nominal power of the transformer will always remain the manufacturer's value. In this case the "generic" relative values will be updated as a function of this real Transformer nominal power. -

There may be new features in the version 8, which were not implemented in the version 7. Now for the modification of the Rshunt and Rserie values, this was a feature of the software which has been mpdified. In the version 7, when they were judged not quite correct, these values were updated to default ones. This is no more the case in the version 8.

-

The files created in the V8 cannot be used with the version 7.

-

You can add a battery in your database from scratch by using "Databases => Batteries => New". But you are strongly advised to choose a similar battery in the database, modify its parameters according to your own component datasheets, and save this as a new battery. For defining an hybrid system, you should choose the button "Storage" in the project's dialog, and probably choose the option "Self consumption" for your case.

-

No, in the present time PVsyst doesn't consider the charging of the battery from the grid.

-

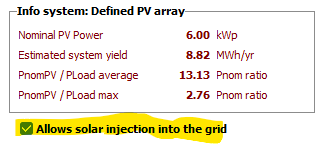

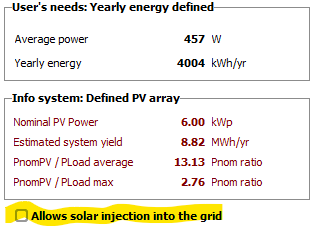

This is quite normal as you have defined a grid limitation of 1 kW (for a system of 200 kWp, 180 kWac). You can notice that the apparent value is 79 kVah, to be compared to a global delivery to the user of 224 MWh, i.e. 0.04%. Please note that you have the opportunity of completely forbid the injection to the grid when you define the self-consumption:

-

Battery being under-utilized in self-consumption simulation

André Mermoud replied to Dean O's topic in Problems / Bugs

Yes indeed, the battery model of PVsyst uses information which is not always present on the datasheets. Some datasheets are really very brief. When you have to define a battery by yourself, you are advised to start from an existing battery, and adjust the relevant variables (mainly technology, kind of battery, number of cells in series and parallel, internal resistance (check dafault), self-discharge (check default), lifetime (numbe of cycles), sizes and weight -

about PV module ageing parameters : Imp/Vmp contributions

André Mermoud replied to Chen's topic in Problems / Bugs

You can find some data about the current and voltage degradation in the works, namely, of the TISO in Switzerland. For example in this publication: https://www.researchgate.net/publication/256080133_TISO_10_kW_30_years_experience_with_a_PV_plant